Pavonine 开发了一种融合了镜片功能的全新概念偏光片。这种产品不需要使用玻璃镜片,可用于扩展现实(XR)设备的模块,有望减轻重量和厚度。

Pavonine 宣布于17日推出了一种名为“热成型曲面偏光片”的 XR 头戴设备模块,该模块在网格偏光片上同时实现了镜片和反射偏光功能。

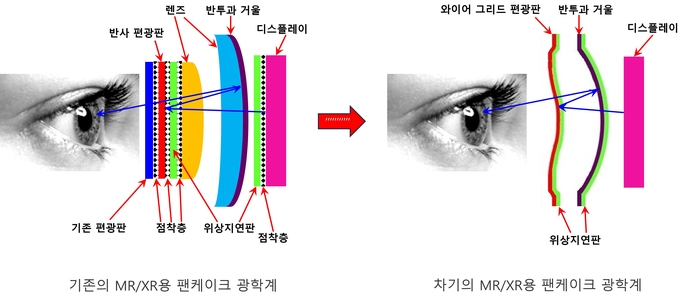

网格偏光片是一种在非常薄的金属片上施加纳米图案的材料。公司通过在这种材料上进行球面热成型工艺,制造了一种特殊的偏光片,其中一半光线透过后成为偏振光,另一半则成为反射光。该产品的关键之处在于,它可以替代Pancake光学系统中使用的镜片,无论是玻璃还是塑料。

由于 XR 设备需要与眼睛距离更近,且需要制造较小的光学模块,因此通常采用 Pancake 结构。这种结构通过多次反射光线来保持视场角,同时减少焦距和厚度。

薄膜型反射偏光片原理,通过Pavonine韩国球面热成型工艺增加镜片功能。

Pavonine 利用球面热成型工艺将镜片功能整合到反射偏光片上,原理如上图所示。这种创新的方法使得光学系统更加简化,从而减少了光线损失,提高了透射率,并减轻了重量和厚度。

Pavonine 首席执行官 Lee Seong-joong 表示:“以前,反射偏光膜贴在又重又厚的镜片上,因此在穿过镜片、粘合剂层时,透光率降低,光效率降低,他补充道:“通过将镜片与偏光片两种功能结合起来,我们简化了光学系统的设计,减少了光线损失,提高了透射率,并减轻了重量和厚度。”

Pavonine 正准备使用与韩国纳米综合技术研究院共同开发的300mm(12英寸)硅模具设备进行量产。他们可以每月生产24万片 Pancake 结构的热成型曲面偏光片。

译自:etnews

资料下载:

欢迎您点击此处加入AR/VR通讯录,目前已经有3000多人加入,如歌尔、HTC、OPPO、创维、PICO、字节跳动、黑鲨、联想、耐德佳、灵犀微光、立讯、领益智造、欧菲光、华勤、闻泰、立讯、珑璟光电、舜宇、深圳虚拟现实等,点击下方关键词可以筛选