In recent years, near-eye display products have continually sparked excitement in the tech industry and garnered significant interest from consumers. This particular virtual display technology requires even stricter quality control to meet the experiential expectations of both consumers and industry users.

The primary challenge is that the unique eye-point position of NED requires special lens designs to meet testing requirements.

Typically, optical testing for near-eye display (NED) products involves using a pupil aperture stop to simulate the actual eye position during testing. This setup provides entrance apertures ranging from 2mm to 6mm, simulating the changes in pupil size as observed by the human eye during viewing.By employing this method, it becomes possible to correlate the test results with human perceptual experiences. This requirement is also specified in the IEC 63145 and IDMS technical documents for wearable near-eye display (NED) devices.

The technical details can be referred to for reference:

The special requirements for lenses in near-eye display testing and lens design.

The use of a pupil aperture stop has become a common choice among many testing equipment vendors. However, some issues still persist, causing concerns within the industry.

For example, a considerable portion of lenses are rather bulky.

similar lenses:

In practical testing, this is further compounded by mechanical constraints of NED products, such as eyeglass arms, which impede normal testing procedures and hinder the simulation of eye movement for scanning tests.

On the other hand, to simulate the zooming characteristics of the eye, most manufacturers employ electric motors to drive lenses for zooming. However, not only is the zoom range limited, but more significantly, in some cases, this mechanism also causes the entrance pupil position of the lens to shift away from the eye-point position while zooming.

This might be the last thing a testing engineer wants to hear, or perhaps it's a fact that no one has informed the engineer about!

Due to the aforementioned facts, different laboratories struggle to achieve reproducibility and reliability in NED product testing.

Since 2018, TechnoTeam has been offering a range of near-eye display (NED) lenses designed with front pupil aperture. Despite the leading compact design of LMK cameras, these lenses still encounter similar issues.

The emergence of LMK EyeFit lenses has changed this situation.

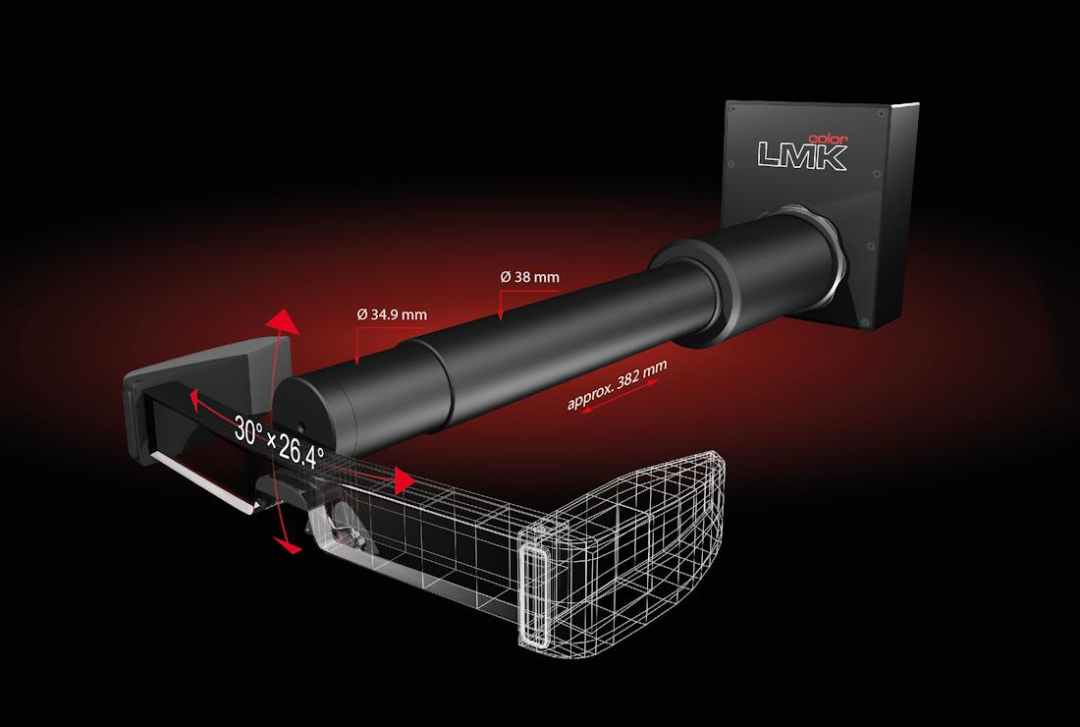

The LMK EyeFit lens is a specialized near-eye display (NED) product testing lens developed and designed by TechnoTeam in 2023. This innovative lens design features a front pupil aperture, with a calibrated entrance pupil diameter ranging from 2 mm to 6 mm, similar to our classic LMK NED lenses.

The greatest advantage of LMK EyeFit lens lies in its unique zooming mechanism, which doesn't rely on electronically controlled stepper motors for driving. This simplifies the process and enhances flexibility during AR/VR/MR testing, significantly improving the reproducibility of tests.

The main features are as follows:

-

Unique focusing mechanism ensures that the entrance pupil position remains unchanged during the focusing process.

-

The lens focusing range covers the entire range of human eye focusing.

-

Compact mechanical dimensions ensure there is no risk of collision during alignment, even when simulating eye movement.

-

The optical quality (MTF) reaches the diffraction limit.

| Lens type | TTNED 40 | TTNED 40 Autofocus |

|---|---|---|

| Focus operation | Manually controlled focus (MFL) | Electronically controlled focus (AFL) |

| Focal length | 40 mm | 40 mm |

| Focal power | 0 dpt. to + 2 dpt. | - 5 dpt. to + 10 dpt. |

| Focus distance | > 500 mm to infinity | > 100 mm to infinity |

| Entrance pupil position | at aperture cap position at the tip of the lens | at aperture cap position at the tip of the lens |

| Entrance pupil diameter | 2 – 6 mm pinhole diameter of the aperture cap (< 2.5 mm diffraction limited) |

2 – 6 mm pinhole diameter of the aperture cap (< 2.5 mm diffraction limited) |

| Field of view (total) | LMK 6-12: ≈ 21.2° (H) × 14.8° (V) LMK 6-30: ≈ 30° (H) × 26.4° (V) |

LMK 6-12: ≈ 21.2° (H) × 14.6° (V) LMK 6-30: ≈ 30° (H) × 26.2° (V) |

| Length of lens body | ≈ 393.5 mm |

≈ 382 mm |

| Diameter of lens body | ≈ 35 mm at entrance pupil position ≈ 50 mm approx. 117 mm behind lens tip |

≈ 35 mm at entrance pupil position ≈ 60 mm approx. 198 mm behind lens tip |

Conventional NED lenses are still available for ordering, primarily offered in two focal lengths. As mentioned earlier, they are based on a NED lens design released in 2018.

Both focal length lenses have been validated in practice as NED lenses. They can be manually focused and calibrated for apertures ranging from 2 to 6mm.

This lens design is more suitable for testing NED component products. Different focal lengths offer varying fields of view and resolutions.

|

Lens type |

TTNED 35 | TTNED 50 |

|---|---|---|

| Focus operation | Manually controlled focus (MFL) | Manually controlled focus (MFL) |

| Focal length | 35 mm | 50 mm |

| Focus distance | > 200 mm to infinity | > 500 mm to infinity |

| Entrance pupil position | at aperture cap position at the tip of the lens | at aperture cap position at the tip of the lens |

| Entrance pupil diameter | 2 – 6 mm pinhole diameter of the aperture cap | 2 – 6 mm pinhole diameter of the aperture cap |

| Field of view (total) |

LMK 6-12: appr. 26° (H) × 19° (V) LMK 6-30: appr. 39° (H) × 29° (V) |

LMK 6-12: appr. 15° (H) × 11° (V) LMK 6-30: appr. 24° (H) × 18° (V) |

| Length of lens body | ≈ 36 mm | ≈ 84 mm |

原文始发于微信公众号(光傲科技):AR/VR/MR Testing Hardware Breakthrough: LMK EyeFit Motorless Zoom Lens Garners Industry Attention