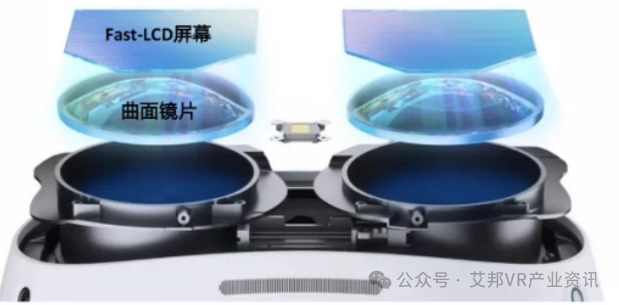

Pancake技术原理

Pancake光学方案实现折叠光路的原理,主要基于4种组件:线性偏振片(LP)、四分之一相位延迟片(QWP)、半反半透镜(BS)和反射偏振片(RP或PBS)。

四分之一相位延迟片又叫四分之一波片,用于将圆偏振光通过四分之一相位延迟,变成线偏振光;反射偏振片用于透过和反射不同的线偏振光;半反半透镜又称分束镜,用于将入射光分成相等的两部分,50%反射,50%透射;线性偏振片则能起到一个过滤的作用,保证只有特定取向的偏振光才能穿透并进入到人眼中。

目前有几种不同的Pancake折叠光路设计的技术实现,包括单片(1p)、两片(2p)和多片式。

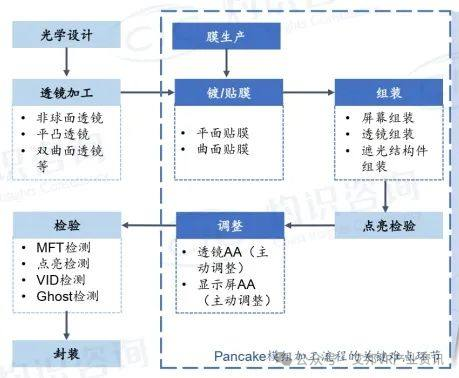

Pancake模组加工

Pancake模组加工关键难点环节包括镀膜/贴膜和组装调整;高质量膜材和贴膜工艺能够实现更稳定的光的偏振态传输。

Pancake模组在组装时需要考虑:

-

所有表面的近轴光轴是否重合

-

非球面轴与近轴系统轴是否重合

-

镜片中心厚度及其间距是否正确

-

偏振元件间的对准是否正确

-

是否达到所需的图像清晰度

-

Pancake 方案光路设计复杂,进行屏幕、透镜等组装时需要严格按照既定光路设计完成,细微差异便会导致光学模组整体的光路变化,因此对组装调整环节的要求较高。高精度 AA 设备在 Pancake 组装过程中起到关键的效率和良率提升作用。

AA组装制程

AA制程,即Active Alignment,主动对准,是一项确定零配件装配过程中相对位置的技术。在光学领域,AA制程通过六轴平台控制并调整镜片组和成像芯片的相对位置与姿态,精确控制镜片组的光轴中心、镜片组的位姿,包括光学焦距等关键参数,使其与成像芯片的位置得到精确控制,最终使对位耦合出来的光学模组成品获得最佳的成像效果。

AA主动对准技术可有效的减小整个模组的装配公差,有效的提升光学产品一致性。

Pancake镜头因为使用了折叠光路设计使得镜头的组装难度指数级增加,最终效果受镜片每个面之间的相对位置关系(6DOF)非常大,稍有误差都会导致用户的体验大打折扣。

为实现光学镜头和屏幕的高精度组装,通常需要光学级AA设备组装。在VR光学模组AA组装领域,一般是使用仿人眼相机(NED)或者矩阵式相机(Telescope)二者其中之一。

矩阵式相机(Telescope)方案:

优点:多个相机,可以自定义多视场,如0F,0.2F,0.3F,0.4F,0.5F,0.6F,0.7F,0.8F,0.9F,1F等。可精确量测单一视场的MTF值。

缺点:多个相机之间需标定其间关系,难度较大;无法测试整体模组的亮度均匀性。

仿人眼相机(NED)方案:

优点:单一相机,可覆盖VR模组整个画面视场,可以直接测试出VR模组整体亮度均匀性、光心(OC)和畸变。

缺点:由于近眼相机其镜头景深大,无法精确的判定AA峰值和虚像距(VID),导致无法精确定位AA时位置,最终测出的MTF结果准确性差。

AA设备供应商

1. 昆山康泰达电子科技有限公司

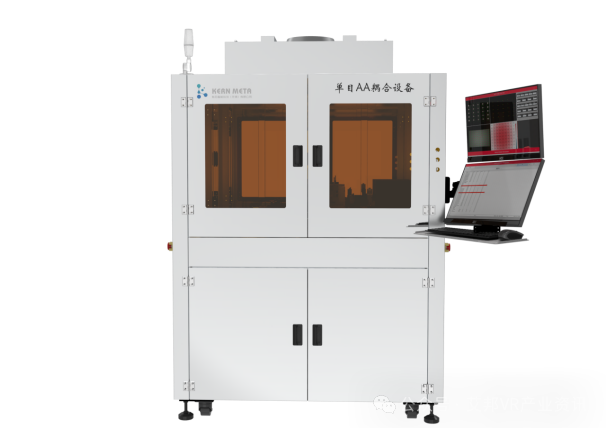

康泰达智能科技有限公司成立于2019年4月。公司坐落于江苏省昆山市张浦镇德国工业园,是一家专注于元宇宙、精密光学光电领域的自动化设备研发、设计、生产、销售为一体的高科技企业。

公司突破光学、图像测试算法、AI图像处理算法等技术,已经取得了XR领域AA技术的绝对优势,针对XR光机模组及终端厂对自动化生产线设备需求,康泰达基于十年以上精密光学光电行业设备研发经验,前瞻性布局,抢抓机遇,通过两年多不断的研发、迭代升级,现已推出多款自动化设备:AR/VR光机模组AA自动化设备、XR光机/整机成品光学性能检测设备、AR/VR双目合像AA设备、XR光机/整机自动化生产线,目前康泰达与舜宇集团、歌尔声学、耐德佳、微瑞光学等行业头部企业建立深度的合作关系,为多个客户提供用于XR生产的AA设备,市占率目前超过35%。

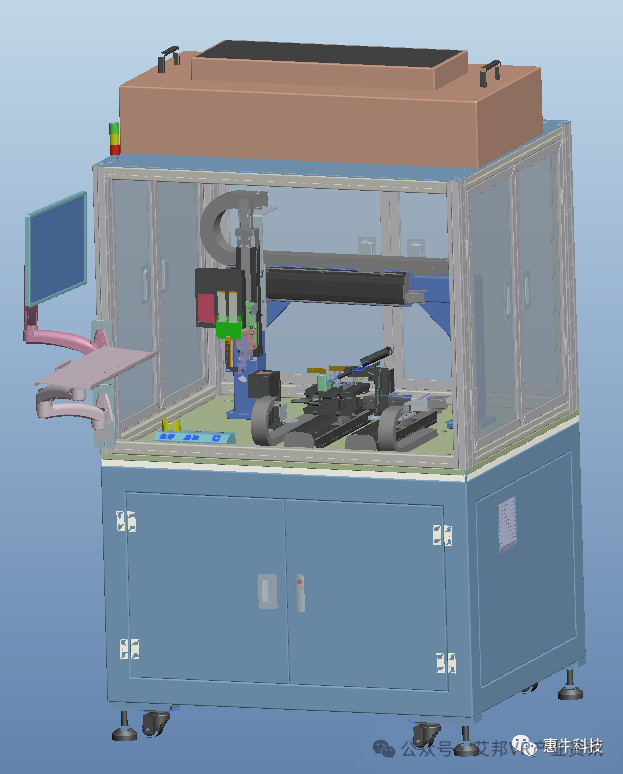

2. 深圳惠牛科技有限公司

2023年12月,惠牛科技浙江武义百级/千级无尘生产基地正式动工,占地面积6000㎡,预计在2024年Q1投入生产,最大年产能可达50万套模组。惠牛科技武义生产基地将引入惠牛自研的AA设备和自动组装设备,进一步提高模组装配精度和自动化水平,满足大客户出货要求。

新生产基地将配置注塑机、镀膜机、CNC机床、曲面贴膜机、自研HNOTS光学测量平台等设备,拥有完整的生产制程,覆盖注塑、镀膜、清洗、加工、组装、测试等环节,量产的模组包括AR-Birdbath系列、VR-Pancake系列和AR光栅波导系列。

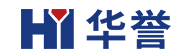

3. 昆山华誉自动化科技有限公司

昆山华誉自动化科技有限公司是一家国家高新技术企业,公司一直致力于组装、检测、焊接、点胶等自动化工艺研发,是一家能提供整线工业4.0智能工厂解决方案的国家高新技术企业,2017年被认定为昆山市研发机构,并有拥有发明专利四十多项,软件产品十多项。合作客户包括水晶光电、歌尔等。

2019年华誉开始涉足研发光学检测领域,从汽车车灯检测方向开始着手被动发光产品的光品质控制系统和信息化管理、工效学研究和优化设计,并以此为基础快速拓展至AR/VR及HUD等的工效学研究与设计、产品研发与装备制造。华誉AA组装设备利用多个相机采用穹顶结构,全新高速高精度运动机构,可以从6个自由度上对前端工艺组装公差进行调整补偿。

4. 深圳中科精工科技有限公司

http://www.ait-prime.com/

深圳中科精工科技有限公司是集研发、设计、制造、销售及服务于一体的国家高新技术企业,专精特新企业。中科精工为客户提供智能封装、测试及检测等系列设备及定制一站式整体解决方案。公司产品广泛应用于智能手机、智能穿戴设备等消费电子领域,以及车载电子、元宇宙、机器视觉、半导体、自动驾驶领域。

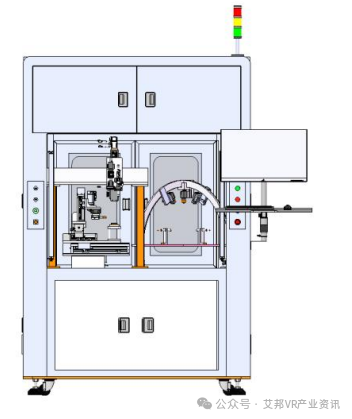

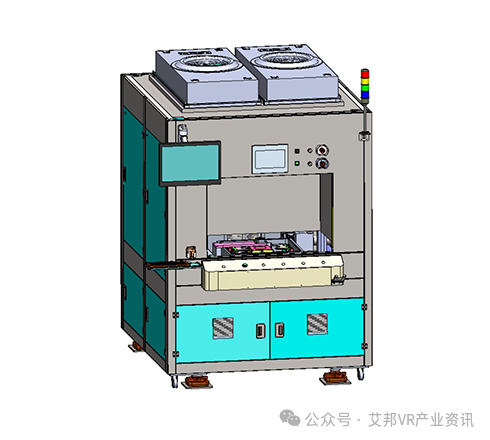

中科精工AR VR AA设备主要用于AR/VR产品的AA制成工艺,全自动上下料,六自由度调整,搭载全自动精密点胶系统,适合研发、实验室,新产品试产及验证、量产。

5. 珠海广浩捷科技股份有限公司

珠海广浩捷科技股份有限公司成立于2009年3月6日,是一家以成像质量分析与机器视觉等为核心技术的自动化智能装备制造商。

广浩捷AR/VR光学模块组装测试设备基于自主研发的高速高精度六轴平台,多项专用于XR光学模块的全新AA算法及图像分析算法,可提供涵盖Pancake偏振膜自动曲面贴膜,Pancake镜片极化轴角测试,光机合色AA组装,光机与波导镜片AA组装,光机与BB镜片AA组装等XR先进光学模块核心制造工艺设备及品质管控设备,满足客户超精密制程需求。

6. 深圳科瑞技术股份有限公司(002957)

https://www.colibri.com.cn/

科瑞技术创立于2001年,是工业自动化设备及智能制造整体解决方案的全球供应商。公司主要从事工业自动化设备的研发、设计、生产、销售和技术服务,以及精密零部件制造业务。产品主要包括自动化检测设备和自动化装配设备、自动化设备配件、精密零部件。围绕“3+N”业务战略布局,业务主要聚焦于移动终端行业和新能源行业。

科瑞AA设备采用高像素高分辨率测试仪器加专用AR光阑前置镜头,自研全自动 6 轴对位平台及 AA 算法,高性价比,可搭配多轴点胶固化系统,满足不同形状产品需求,柔性化设计,兼容多产品快速切换, 兼容手动和自动上下料,支持条码管理系统和 MES 定制系统。功能:视觉识别、光机模组与光波导AA、点胶与固化。

7. 深科达智能装备股份有限公司(688328)

深科达智能装备股份有限公司于2004年成立,主要业务为3C面板智能设备、半导体封测设备、自动化核心部件。主要从事智能装备及自动化零部件研发、设计、装配、调试集成、销售、服务等,客户涵盖京东方、JDI、华星光电、天马等国内外知名企业。

深科达通过近几年在VR生产设备的研发,目前已能提供3D VR热成型贴合设备、3D AA胶合设备以及IJP设备等,上述设备用于VR眼镜Pancake光学模组生产端,主要客户为国际一线知名客户。

8. 无锡众景腾电子科技有限公司

无锡众景腾电子科技有限公司成立于2017年,公司依托自动化上市企业的整合能力,联合研究院、高校实验室、材料实验室等在喷墨打印领域、EHD领域、UPD领域、偏振光学领域、MR&AR光学领域等进一步进行深耕应用落地和开拓创新。

公司有完善的MR光学实验室、喷墨打印实验室,高分子材料实验室等,所有实验室服务于新技术落地工艺的开发工作。截止目前,众景腾已经实现光学镀膜、胶水打印、油墨印刷、纳米银打印、医用药液打印、偏振光学光轴对位、曲面成型贴膜、六自由度光学对位矫正等的工艺技术开发和落地,广泛应用于显示、半导体、锂电、医疗等不同领域。

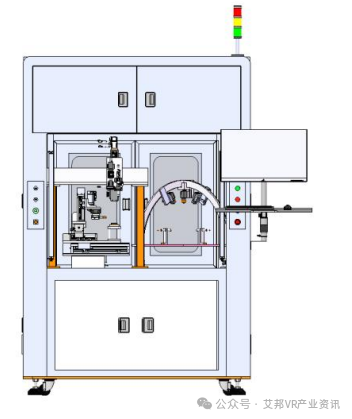

9. 有芯智能科技(无锡)有限公司

有芯智能,一家成立于2021年的新兴科技企业,凭借着团队成员在VR/AR及核心光学领域的深厚积累与探索,推出多款VR Pancake Apollo系列光机模组和AR BB模组。全面布局VR Pancake,AR BB、LBS、CPO等先进光学技术路线,可以根据合作伙伴的需求提供ODM/JDM/OEM服务。

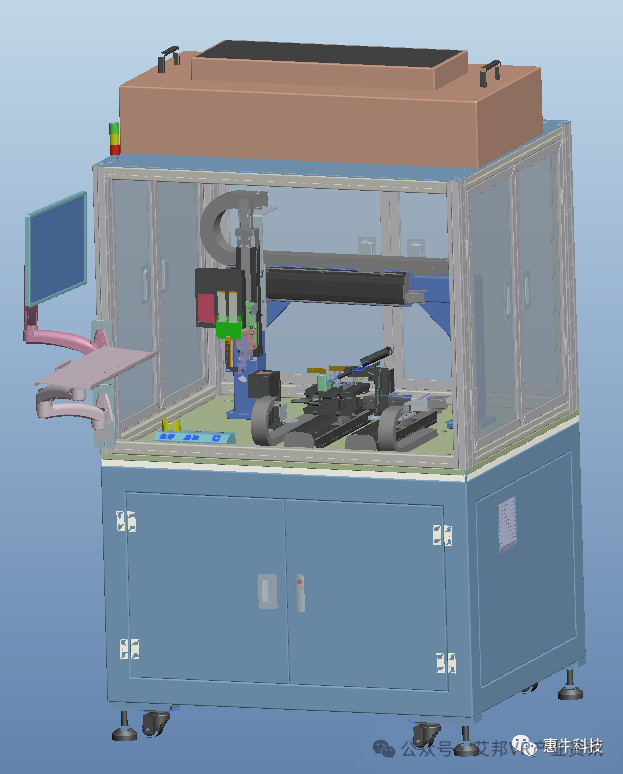

针对XR光机行业,生产效率低,良率低,成本高的痛点,公司依托于团队光学、电子、机械、软件、半导体的背景经验,结合光学产品的工艺特点,自制了国内首条完整的高兼容先进光学自动化产线,完整覆盖光机制造核心工艺,包括自动曲面贴膜、自动AA耦合、虚像距测试等自动化设备。

有芯自主开发VR单目AA耦合设备,采用自主研发的仿人眼视觉系统,搭配高精度AA六轴平台,拥有AA核心算法,具备异形画胶及自动胶线检测功能,能实现自动抓取、AA、画胶、检测、固化等动作。

本文信息来源各公司官网、网络等,艾邦智造编辑

原文始发于微信公众号(艾邦VR产业资讯):VR Pancake制程及国内AA组装设备供应商

![]()

![]()

![]()

![]()