As AR products become increasingly wearable, more and more designs are taking the form of glasses, including some lightweight and flip-up VR headsets. The hinge is an important component in these designs.

GoerTek's Flexible VR Glasses feature a foldable design achieved through hinges.

The function of a hinge

1. The hinge provides folding and storage functionality for AR glasses. The design of the hinge must avoid the risk of damaging internal signal wires during folding and unfolding, as well as preventing the signal wires from being exposed externally, which could affect the aesthetics of the product.

2. There are significant differences in users' head shapes, so the design of the hinge needs to accommodate various head shapes while ensuring a certain level of clamping force to enhance user comfort during wear.

3. As AR products continue to incorporate more features, hardware becomes increasingly complex, and overall power consumption rises, the demand for heat dissipation also increases. However, the internal space of glasses is limited, with hardware components filling both the frame and temples. Many signal wires need to pass through the hinge to connect the hardware on the frame and temple sides. This requires the hinge to have reliable threading capabilities and excellent thermal conductivity. Additionally, the hinge should withstand multiple bends without compromising the performance of signal transmission and heat dissipation.

4. AR glasses have a design requirement for lightweight and compactness, and therefore, the hinge design should also be as lightweight as possible.

来源:歌尔

Hinge Manufacturing Process

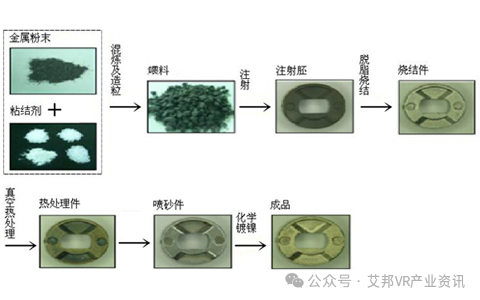

Metal Injection Molding (MIM) Technology

MIM technology is suitable for mass production of small, intricately-shaped precision metal components with complex three-dimensional geometries. It offers unique technical advantages in component design and development.

Metal Injection Molding (MIM) Process

-

The components have a high degree of geometric freedom, enabling the one-step formation of complex-shaped metal parts. -

MIM products have uniform density and excellent surface finish, with a surface roughness reaching Ra 0.80~1.5um. They typically weigh between 0.1~200g. They exhibit high dimensional accuracy (±0.1%~±0.3%) and usually require no further machining. -

The raw material utilization rate is high, and the production process is highly automated with simple procedures, enabling continuous mass production. -

The product quality is stable and reliable, with a relative density of 95% to 99%. It can undergo heat treatment processes such as carburizing, quenching, and tempering. -

The product exhibits high mechanical properties such as strength, hardness, and elongation.

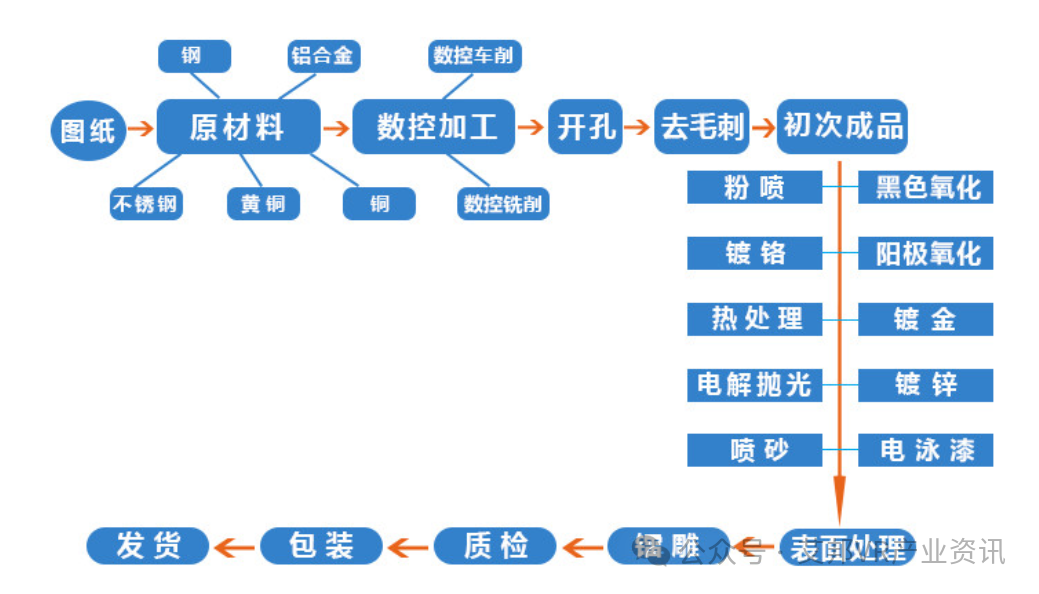

Computer Numerical Control (CNC) Machining

CNC machining involves computer-controlled motion of cutting tools to remove material from a workpiece and create finished parts. Hinge products typically involve complex geometric shapes such as spirals, spheres, curves, etc. The multi-axis capability of CNC technology allows for easy handling of these shapes, enabling the manufacture of complex geometries. Compared to traditional machining methods, CNC offers advantages including improved precision, consistency, and speed.

CNC technology can accommodate the precision, complexity, and production efficiency required for hinge manufacturing. It enables precise cutting and shaping, ensures consistency in quality, enhances production efficiency, and allows for controlled machining processes.

The CNC machining process

Related suppliers

Jiangsu Jingyuan Technology Co., Ltd. (Stock Code: 300709)

Jiangsu Jingyuan Technology Co., Ltd. (abbreviated as GIAN), established in 2004, primarily specializes in providing customized MIM core components and assembly products with high complexity, precision, strength, and exquisite appearance for mass consumption in the fields of smartphones, wearable devices, automobiles, and other industries.

Jingyuan Technology primarily focuses on MIM (Metal Injection Molding) products. In 2019, it established the Jingyuan Transmission Division, and in 2022, Jiangsu Jingyuan Power Systems Co., Ltd. was formally established. This subsidiary specializes in the design and manufacturing of mechanical and electric transmission mechanism products, providing customers with comprehensive transmission system solutions.

Kunshan Keson Science and Technology Co., Ltd. (Stock Code: 603626)

Keson Technology is a high-tech enterprise specializing in the research, manufacturing, and service of precision structural components. The company was listed on the main board of the Shanghai Stock Exchange on February 9, 2017, with the stock abbreviation "Keson Technology" and the stock code "603626".

Keson Technology relies on manufacturing processes and technologies such as precision die casting, forging, stamping, CNC machining, laser cutting, laser welding, MIM (Metal Injection Molding), and precision injection molding. Supported by precision mold design and production, the company provides research, manufacturing, and partial assembly services for precision metal and plastic structural components required for terminal products in consumer electronics (including heated non-combustible electronic cigarettes, VR), medical devices, automotive (including new energy vehicles), and other industries for both international and domestic renowned clients such as Apple, Huawei, Amazon, Google, Meta, and Medtronic. The company's consumer electronic products include casings, midframes, midplates, buttons, logos, hinges, and other components for smartphones, laptops, tablets, smart headphones, smart speakers, electronic cigarettes, VR devices, and other terminal products.

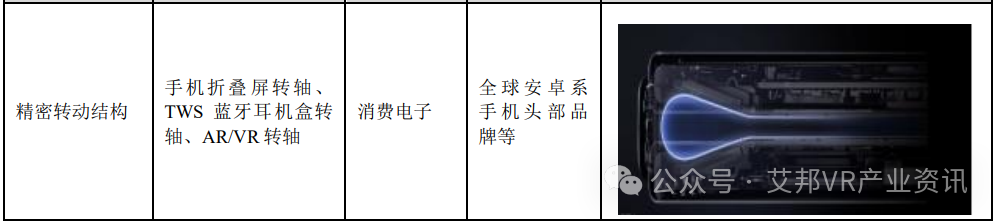

Fushide Corporation Limited (Stock Code: 6805.TW)

Fushide Corporation Limited was established in 2001 and is currently a subsidiary of Qisda Corporation (Stock Code: 3017). Fushide specializes in the design and manufacturing of various metal stamping products, with its main products being hinge components for folding smartphones, laptops, and tablets. It has a significant customer base consisting of well-known computer and mobile phone manufacturers.

Fushide's bearings are applied in various consumer electronics (3C) products including smartphones, tablets, laptops, AR/VR glasses, and headphone cases. Approximately 80% of their products are used for hinge assemblies in folding smartphones. Currently, Huawei's main suppliers for hinge components in folding screen smartphones are Zhaoli and Fushide.

Guangdong Lingyi Intelligent Manufacturing Co., Ltd. (Stock Code: 002600)

Guangdong Lingyi Intelligent Manufacturing Co., Ltd. has developed new advantages in smart manufacturing, combining materials from the upstream, precision functional components and structural components from the midstream, to modules and chargers in the downstream. It provides customers worldwide with one-stop smart manufacturing services and solutions. The company's precision functional components have maintained a leading position in the global consumer electronics market in terms of market share and shipment volume for many years. Lingyi has multiple product lines including keyboard modules, heat dissipation modules, backlight modules, RF modules, motor modules, hinge modules, acoustic modules, touchpad modules, and wireless charging modules, which are widely used in various products.

Lingyi Intelligent Manufacturing has stated that it has entered the supply chain of leading VR/AR customers both domestically and internationally. Its products mainly include structural components (such as hinges), functional components (such as acoustics), and complete machine OEM services.

Kunshan Weishuo Hengji Intelligent Technology Co., Ltd. (Stock Code: 872759)

Kunshan Weishuo Hengji Intelligent Technology Co., Ltd. is a high-tech enterprise specializing in the research, development, production, and sales of hinges. Established in Kunshan in 2009, it has research and development centers in Kunshan (Jiangsu), Chongqing, and Taiwan, as well as manufacturing plants in Kunshan (Jiangsu), Wansheng (Chongqing), Jiashan (Zhejiang), Dongguan (Guangdong), and Vietnam. Additionally, it has offices in Beijing and Hefei. The company was listed on the New Third Board on May 11, 2018, with the stock code 872759. On March 31st, the company suspended its IPO process on the Shenzhen Stock Exchange ChiNext Board.

The company is dedicated to various precision hinges, focusing on the research and manufacturing of hinges for laptop computers. Its products can be widely used in laptops, folding phones, automotive accessories, smart home devices, and various consumer electronics. The company has gained high recognition from customers such as Lenovo, Samsung, Dell, HP, Xiaomi, and Asus.

The hinge mechanism for VR glasses

Dongguan Suocheng Electronics Co., Ltd.

Dongguan Suocheng Electronics Co., Ltd., established in 2009, is a national high-tech enterprise specializing in the customization, research, and production of hinges. The company has a sound management system, advanced production equipment, and precision testing instruments. It has obtained ISO9001/14001, IATF16949 system certification, and has been awarded 35 patents. It has realized a full-process production mode from product research and development, mold manufacturing, sheet metal stamping, CNC lathe, powder metallurgy, spot welding, laser engraving, to finished product assembly.

The company has over 20,000 types of hinges and 128+ industry cases. Its products are widely used in various fields such as 3C digital, automotive, robotics, industrial control, security, audio-visual instruments, equipment, outdoor cabinets, smart wearables, and home appliances. It has established long-term partnerships with over 1,000 enterprises including Huawei, BOE, Hikvision, Volkswagen, Weltrend, Mindray, Zhaoli, and Weiyida, and its products are sold both domestically and internationally.

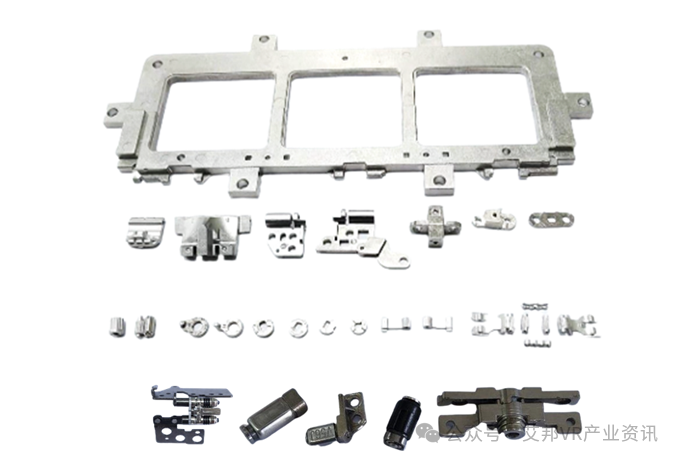

AR glasses hinge components

Shenzhen Yuanzhao Technology Co., Ltd.

Shenzhen Yuanzhao Technology Co., Ltd. was founded in Shenzhen in 2015. Its main business areas focus on the research, development, and manufacturing of hinges (HINGE) as well as the processing of precision metal components. Yuanzhao Technology is committed to providing comprehensive hinge services to customers in various industries including laptop computers (NB), LCD monitors, smart homes, medical health, LED lighting, automotive electronics, etc. This includes manufacturing, research and development, sales, and services. The product range includes a full series of damping hinges, slides, hinges, MIM structural components, and intelligent rotating structures.

The hinge mechanism for VR glasses

Zhaoxinchixi Intelligent Technology Co., Ltd.

![]()

Zhaoxinchixi Intelligent Technology Co., Ltd. (JIT for short) is a company whose core operating team comes from the top 2 enterprises in the Metal Injection Molding (MIM) & Hinge industry in China. They possess senior research and development design capabilities in the industry and have rich practical experience in handling high-difficulty, large-volume projects in the MIM & Hinge industry. JIT focuses on the MIM & Hinge industry and is committed to using Metal Injection Molding (MIM) technology to produce small, three-dimensional complex, high-performance structural components. They provide high-cost-effective MIM parts and Hinge components in large quantities, and offer technical support and manufacturing services throughout the entire process from early-stage ESI project analysis to mass production.

JIT is rooted in the smart hardware industry, serving industries such as smartphones, smart bracelets, smartwatches, as well as the medical, tool, automotive, and IT industries. They strive to become a highly competitive MIM & Hinge professional manufacturer within 5-10 years.

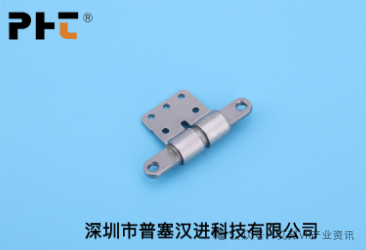

9. 深圳市普塞汉进科技有限公司

Shenzhen Pusaihanjin Technology Co., Ltd. was established in April 2003. It is a professional hinge (HINGE) design and manufacturing enterprise, and one of the earliest and most diverse mobile phone hinge manufacturers in China.

Currently, the company has 120 employees and occupies a factory area of 3000 square meters. It operates six automated assembly lines, with a monthly production capacity of 3 million units for mobile phone hinges and 1 million units for other hardware hinges. The company possesses comprehensive production testing and experimental equipment, including torque curve detectors, dedicated torque inspection instruments for mobile phone hinges, salt spray testing machines, hinge life testing machines, hardness testers, CNC lathes, dedicated milling machines, punch presses, injection molding machines, as well as grinding machines, milling machines, wire cutting machines, and other comprehensive mold processing equipment.

Hinges specifically designed for VR devices

Shenzhen Flande Technology Co., Ltd.

Shenzhen Flande Technology Co., Ltd. was established in 2015 and is located in Shenzhen, Guangdong Province, China. Over the past decade, the company has been dedicated to the research, development, production, and sales of hardware accessories. It is a comprehensive technology company that integrates manufacturing, domestic and international trade, and e-commerce. Our products have been widely used in various products such as laptops, tablets, smartphones, cases, AR/VR devices, desk lamps, drones, POS systems, headphones, and automobiles. Additionally, they have applications in fields such as healthcare, outdoor equipment, and military.

More industry-related manufacturers are welcome to scan the QR code and join the group for further additions.

The original article was first published on the WeChat official account (Aibang VR Industry News):Top 10 AR/VR hinge suppliers