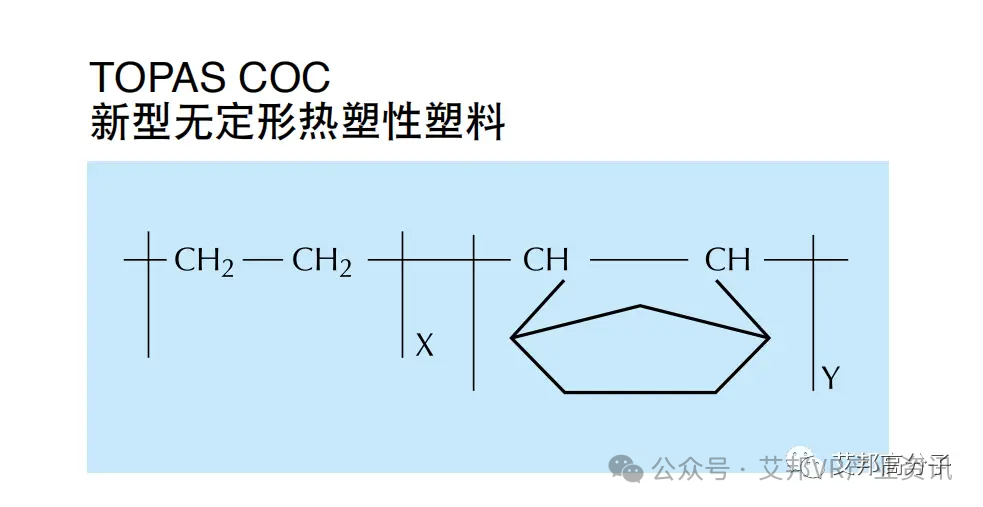

Cycloolefin copolymers are a class of amorphous polymers formed by the copolymerization of ethylene or α-olefins with cycloolefins. The main chain contains a large number of rigid cyclic structures and does not contain any polar groups or carbon-carbon double bonds. Therefore, it has many outstanding properties such as high transparency, high chemical stability, high thermal stability, low birefringence, low density, low moisture absorption, and low dielectric loss. It is widely used in industries such as medical, AR/VR, automotive lenses, consumer electronics, packaging, and semiconductors.

As an amorphous, highly transparent copolymer resin, cycloolefin polymers exhibit excellent optical properties. The transparency of cycloolefin polymers can rival that of PMMA and PC, while also having a higher glass transition temperature (Tg). This means that under similar transparency conditions, cycloolefin polymers have better heat resistance than PMMA; and under similar heat resistance conditions, they exhibit better transparency than PC materials.

In optical applications such as AR/VR and automotive lenses, optical-grade cycloolefin copolymer materials have the advantage of being lightweight and highly moldable compared to traditional optical glass. This makes them the preferred choice for manufacturing optical components and can also be used for polarizer protective films, display screen films, and more.

Title: Comparison of Optical Material Performance

|

Indicators |

COC |

PS |

PC |

PMMA |

|

General Indicators |

||||

|

Density (g/cm³) |

1.02 |

1.05 |

1.2 |

1.2 |

|

Flexural Modulus (Msi) |

0.5 |

0.45-0.5 |

0.34 |

0.45 |

|

Tensile Strength (ksi) |

9 |

6.4-8.2 |

9 |

10 |

|

Elongation (%) |

3-10 |

2-4 |

80 |

5 |

|

Impact Strength (ft-lb/in) |

0.4 |

0.4 |

5-16 |

0.3 |

|

Heat Deflection Temperature (°C) |

75-160 |

75-94 |

142 |

92 |

|

Glass Transition Temperature (°C) |

85-170 |

80-100 |

150 |

105 |

|

Shore Hardness |

89 |

75-84 |

85 |

100 |

|

Water Absorption (%) |

0.01 |

0.1-0.3 |

0.04 |

0.1 |

|

Optical indicators |

||||

|

Total Light Transmittance (%) |

92 |

91 |

88 |

92 |

|

Haze |

1 |

3 |

1 |

1 |

|

Refractive Index |

1.53 |

1.59 |

1.586 |

1.491 |

|

Abbe Number |

56 |

31 |

34 |

61 |

|

Birefringence |

低 |

可变 |

可变 |

低 |

Data source: ACMI, CNKI

According to statistics, more than 20,000 tons of cyclic olefin copolymer products were consumed in China each year. However, the core technology of this material is controlled by foreign companies. The domestic market mainly relies on imports, the cost remains high, and the demand for domestic substitution is high.

Topene Technology breaks the monopoly on cyclic olefin polymer technology

Realize domestic substitution

TopOlefin is the first and currently the only company in China to achieve independent and controllable industrial production and manufacturing of the entire cyclic olefin copolymer chain.

Topene Technology is a national high-tech enterprise and a "specialized, special and innovative" small and medium-sized enterprise in Zhejiang Province. It consists of the Electronic Information Materials Industrialization Research Institute and three wholly-owned subsidiaries. It has a postdoctoral workstation and a provincial engineering research center. It is a rare domestic Advanced high-end polymer material R&D and manufacturing platform.

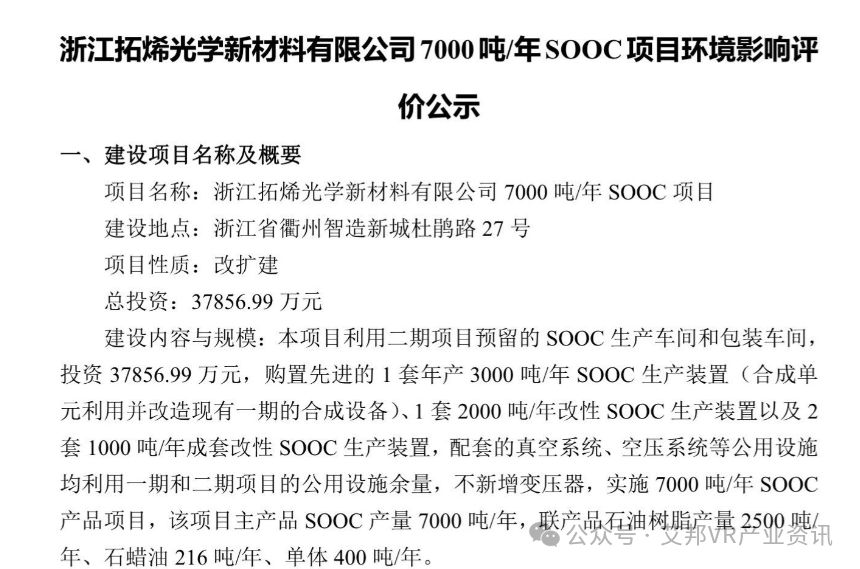

On April 28, the environmental impact assessment of Topene Technology's 7,000 tons/year SOOC project was announced. The project is located in Quzhou Intelligent Manufacturing New City, Zhejiang Province, with an investment of approximately 379 million yuan, and is expected to be put into operation in 2025.

Previously, Topene Technology has built a cyclic olefin copolymer SOOC production line with an annual output of 3,000 tons and put it into operation. After the project is put into operation, the total production capacity of cyclic olefincopolymers will be expanded to 10,000 tons.。

During the development process, Topine Technology's special cyclic olefin copolymer SOOC (Tomet) has continued to receive support from Hikvision, Sunny Optical, Dahua, Yutong Optical, Lianchuang Electronics, OFILM Optics, Chenrui Optics, etc. With the strong support of domestic head camera and lens manufacturers, large-scale batch supply has been gradually achieved. After this project is fully put into production, it will gradually realize the import substitution of high-end optical resins, filling the gap in the field of domestic high-end optical resins.

Topene plans to expand the annual production capacity of cyclic olefin copolymers to 50,000 tons within five years, and comprehensively deploy optical lenses, AR/VR, medical materials, packaging films, green renewable and other application fields.

At the recent Chinaplas, the International Rubber and Plastics Exhibition, Topene Technology also demonstrated Tomet SOOC and its applications:

原文始发于微信公众号(艾邦VR产业资讯):AR/VR光学材料国产替代,拓烯科技环烯烃共聚物(COC)扩建