As smart wearable products, AR/VR glasses not only need to be light and convenient, but also need to have communication functions. Therefore, AR/VR glasses have high requirements for weight, strength, wave transmittance and other properties.

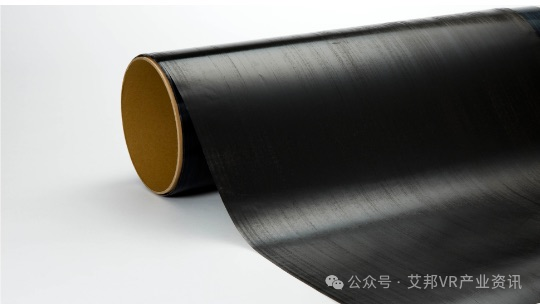

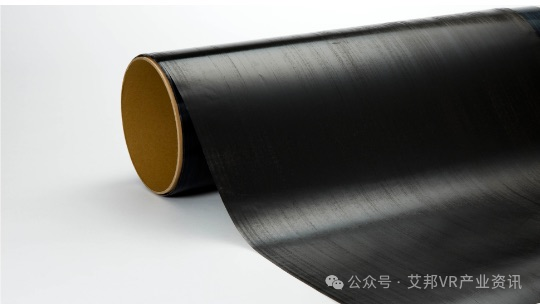

The specific gravity of carbon fiber composite materials is about 1.8 to 2.2, which is light in weight but high in strength and hard. Used for AR/VR glasses housings and frames to provide a thinner, stronger and more durable design. The high strength and rigidity of carbon fiber allows for a thinner design of the device casing, thereby reducing the weight of the device while providing better impact resistance.

Carbon fiber is a fibrous material formed of carbon atoms. Its unique lattice structure gives carbon fiber excellent mechanical properties and chemical stability. Combining carbon fiber with resin can make carbon fiber composite materials (CFRP) . Some high-end electronic devices such as laptops and smartphones have used carbon fiber as a reinforcing material to improve the strength and lightweight of the product.

Figure Carbon fiber composite material, source: Toray

Characteristics of carbon fiber composite materials

-

Lightweight (10 times stronger than steel and 5 times lighter)

-

High rigidity and strength

-

Can be designed for heat resistance of 400°C or higher

-

High impact resistance, can be used as aircraft material

-

Flame retardancy

-

High thermal conductivity

-

High degree of design freedom

-

Disadvantages of carbon fiber composite materials used in consumer electronics

1. Carbon fiber has high dielectric coefficient and strong electromagnetic shielding ability. If a closed space is formed during design, it will affect the internal electronic components receiving and sending signals, affecting the normal function of the product;

2. Carbon fiber has poor processability, and defects such as burrs and delamination often appear at the processing location;

3. The processing cost of carbon fiber composite materials is relatively high.

Carbon fiber structural parts processing technology - hot press forming

Carbon fiber hot press molding is to mix carbon fiber cloth with resin and other materials through prepreg, and then mold it through high temperature and high pressure treatment to form parts or products of various shapes. The entire processing process requires strict control of parameters such as temperature, pressure, and molding time to ensure product quality and performance consistency.

Picture hot press molding machine, source: Xintai Ming

-

Hot pressing: By heating and applying pressure, carbon fiber cloth or yarn is formed into the desired shape in a mold. High temperature and high pressure contribute to the chemical reaction and physical cross-linking between the resin matrix and the carbon fiber, thereby increasing the strength and stiffness of the composite material.

-

Curing: During the hot pressing process, the resin matrix solidifies at high temperatures to form a strong structure. This curing process can form a good combination of fibers and matrix and give the entire composite material better mechanical properties.

-

Control temperature and pressure: The hot pressing molding machine has the function of accurately controlling temperature and pressure to ensure that the composite material can reach the predetermined temperature and pressure conditions during the hot pressing process. This helps ensure the quality and performance of the final product.

Application cases of carbon fiber composite materials in AR/VR

1. Apple Vice President of Industrial Design Richard Howarth mentioned in an interview that Apple Vision Pro has been built with the lightest materials such as magnesium alloy, carbon fiber and aluminum alloy.

2. Goertek’s wireless AR smart glasses reference design based on the Snapdragon®

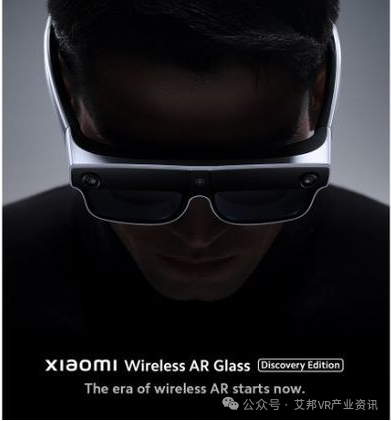

3. Xiaomi will launch the Discovery Edition of wireless AR glasses in 2023, using a series of lightweight materials such as magnesium-lithium alloy structure and carbon fiber components.

The original article was first published on the WeChat official account (Aibang VR Industry News):Carbon fiber composite materials are used in AR/VR glasses